Solutions for Controlling Production Costs of Lithium-ion Batteries: Laser Displacement Sensors for Measuring Electrode Thickness

- Impact of Electrode Layer Count on Lithium-Ion Battery Performance

- Overview of Lithium Battery Production Process

- Laser Displacement Sensors for Measuring Electrode Thickness in Lithium Batteries

- Advantages of Using Laser Displacement Sensors for Measuring Electrode Thickness in Lithium Batteries

- Recommended Laser Displacement Sensors

- GFL-G Series High-precision Laser Displacement Sensors

- GFL-Z Series Laser Displacement Sensors

- Related Photoelectric Sensors

- DB-Y100 | Laser Detector Sensor | DADISICK

- Laser measurement distance|Laser Ranging Sensor|DADISICK

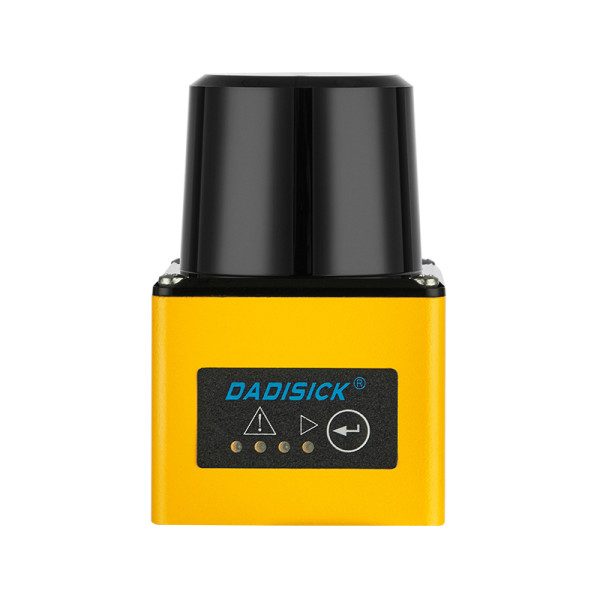

- 5m Obstacle Avoidance|Laser Scanning Radar|DADISICK

- QCE72-40-2840 2BB|Laser Curtain Sensor|DADISICK

Impact of Electrode Layer Count on Lithium-Ion Battery Performance

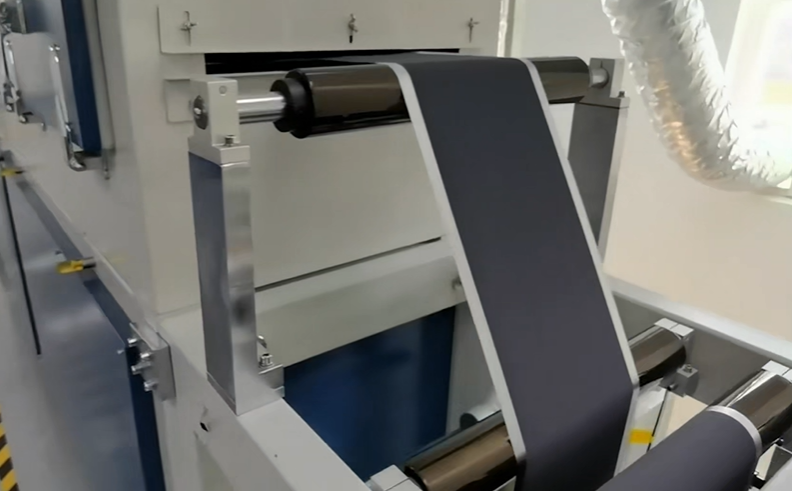

Overview of Lithium Battery Production Process

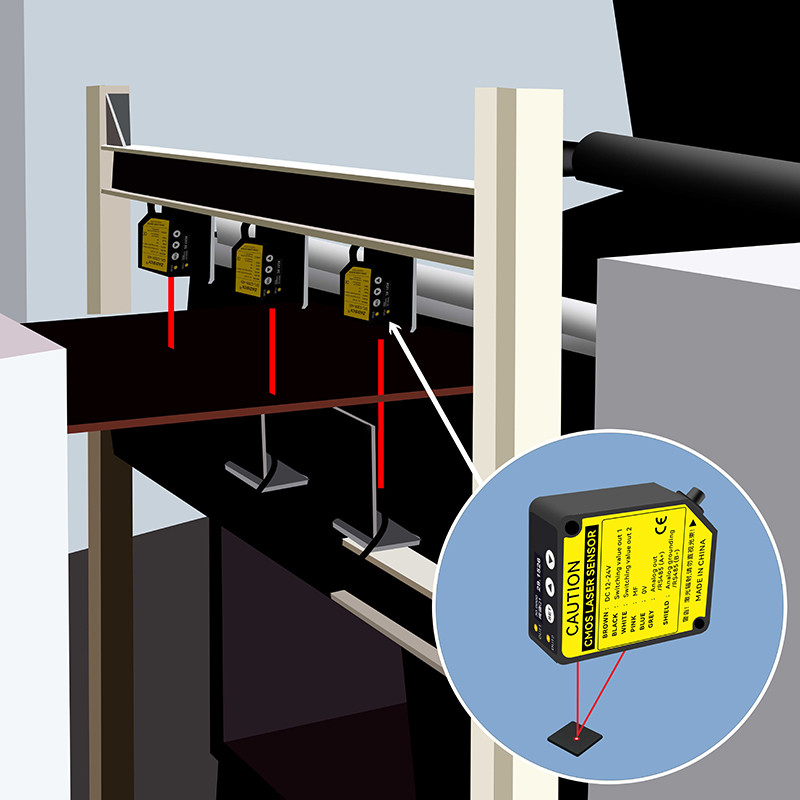

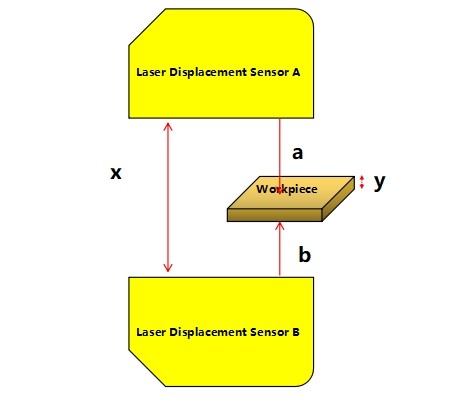

Laser Displacement Sensors for Measuring Electrode Thickness in Lithium Batteries

Advantages of Using Laser Displacement Sensors for Measuring Electrode Thickness in Lithium Batteries

Recommended Laser Displacement Sensors

|

Sensing Distance

|

Resolution

|

Linearity |

Output

|

|

30 mm (±4)

|

2 µm

|

±0.1%f.s. (f.s.=8mm) |

NPN / PNP

Analog RS485 |

|

50 mm (±10)

|

5 µm

|

±0.1%f.5. (f.s.=20mm) |

|

|

85 mm (±20)

|

10 µm

|

±0.1%f.8.(f.s.=40mm) | |

120 mm (±60) | 30 µm | ±0.1%f.s.(f.s.=120mm) | |

250 mm (±150) | 75 µm | ±0.3%f.s.(f.s.=300nm) | |

|

Sensing Distance

|

Repeatability

|

Linearity |

Output

|

|

30 mm (±5)

|

10 µm

|

±0.1%F.S. |

Analog / RS485

|

|

50 mm (±15)

|

30 µm

|

NPN / Analog / RS485

|

|

|

100 mm (±35)

|

70 µm

|

||

200 mm (±80) | 200 µm | ±0.2%F.S. | |

400 mm (±200) | 400 µm / 800 µm | ||